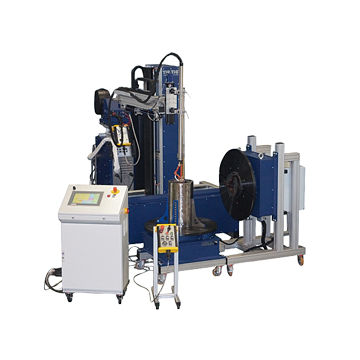

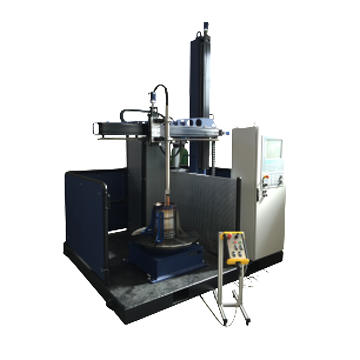

TiPTiG Cladding System

Suitable for CW / HW technology

Process description

The TiPTiG wire feeder sytem provides a linear, steady forward movement of the wire electrode. Simultaniously, this movement is superimposed by a second forward/backward motion.

The result is a kinmatic energy, providing a dynamic and process-stable weld puddle. A second power source provides an resistance-preheated wire electrode, while touching the weld puddle.